Concrete Stairs Treads | Step Treads Sydney & Brisbane

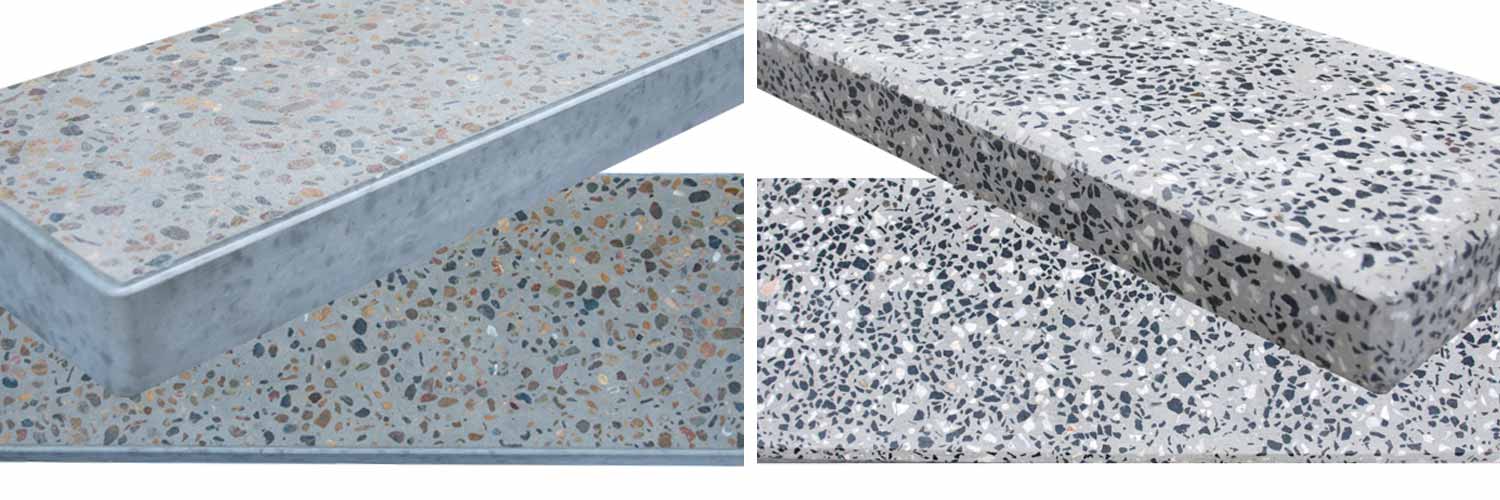

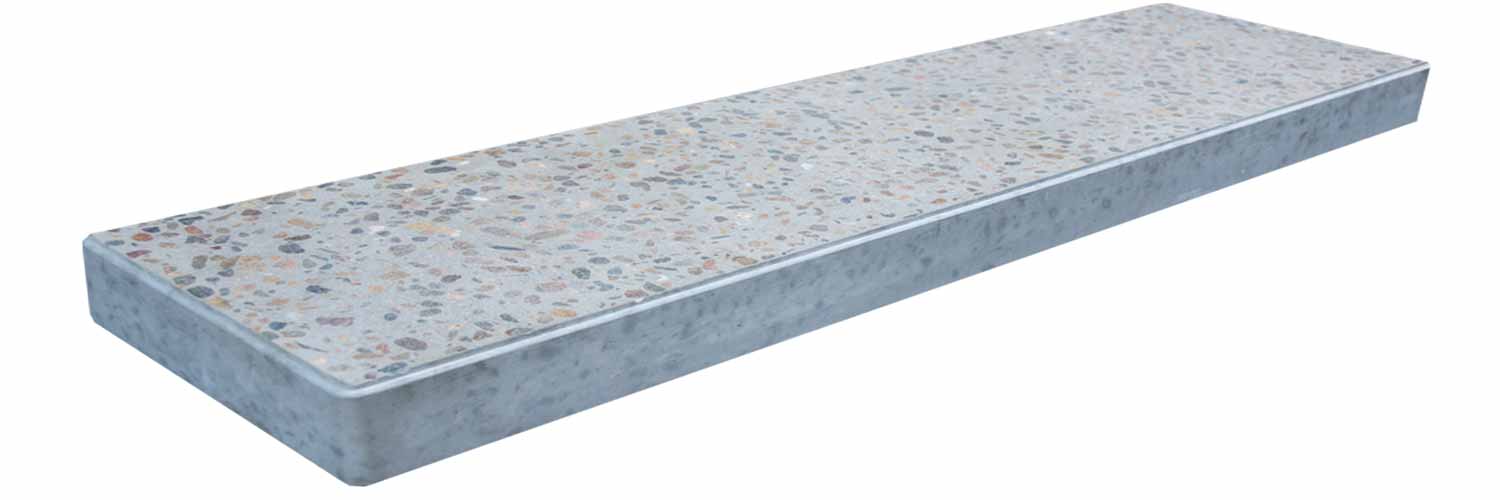

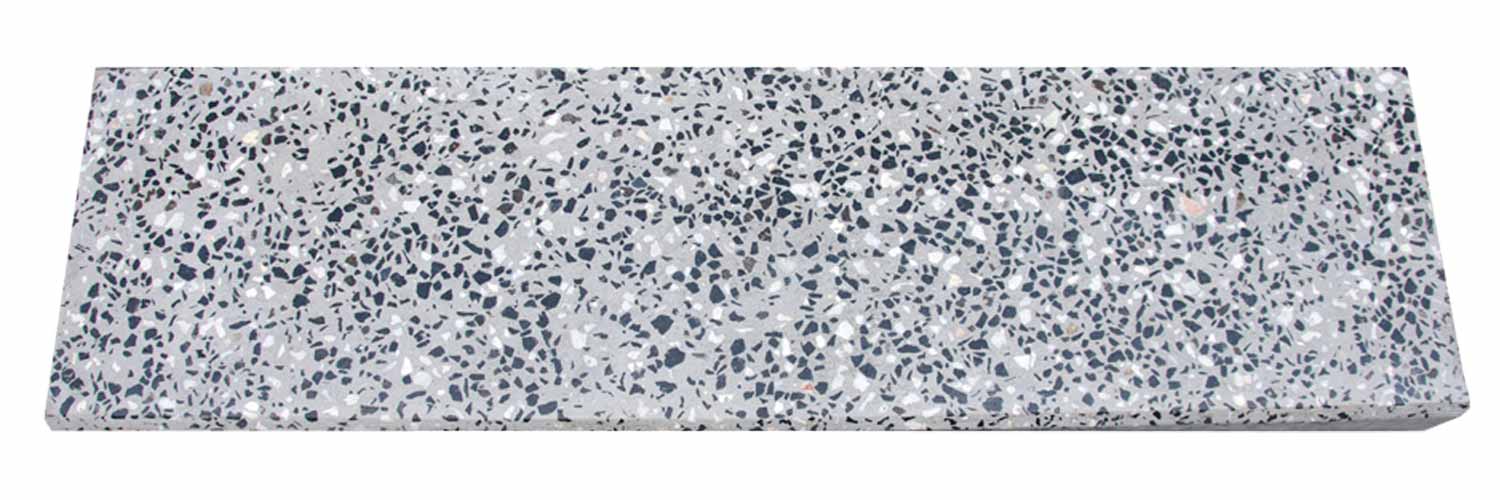

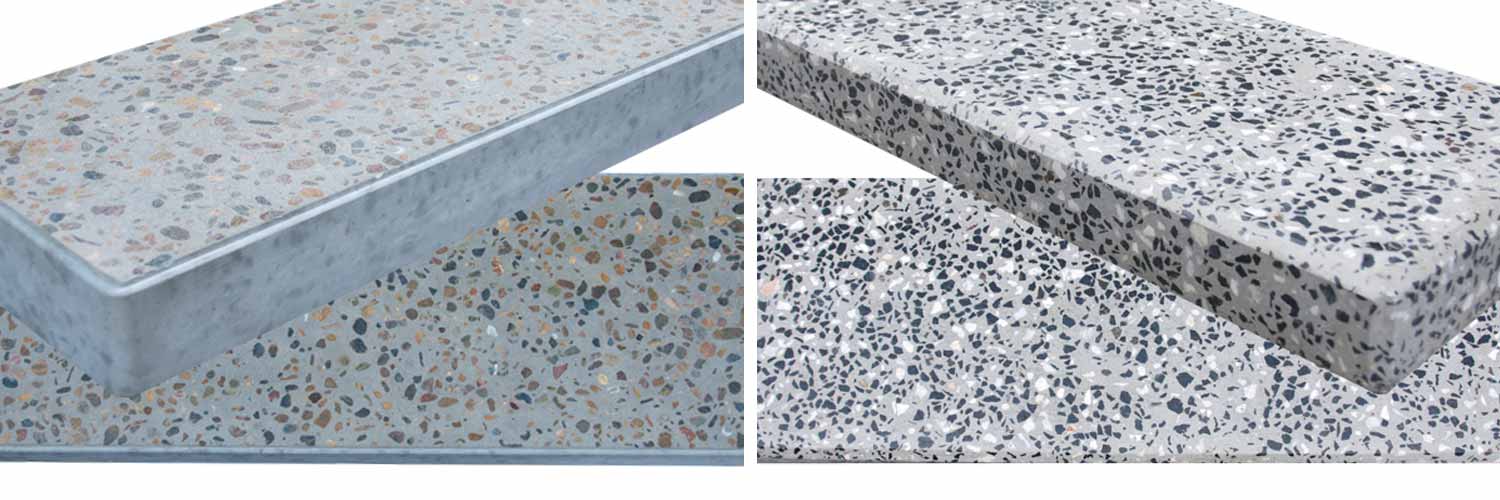

Stone F/X Step Treads have engineered a range of highly durable concrete step treads that are long lasting and will resist wear and tear for many years to come. We have overcome many of the challenges with large scale production of concrete and stone step treads through years of R&D, and a focus on continuous improvement.

- High durability - our treads are built to last for decades.

- Satefy - All our step treads meet or exceed Australian Standards Slip Ratings.

- Rust resistant - our formula is highly resistant to rust and other corrosive issues.

- Designer aesthetics - 120 styles and colours to choose from.

- Custom Options - we can design a style to suit your exact requirements.

- We are the Manufacturer - buy with confidence we stand by our products.

- Low Cost - our treads start at $60 each.

There are 5 reasons to choose our concrete step treads apart from the 120 different colours and various finishes that are available.

- They are comparable in cost to other materials

- Available in different appearances to suit any budget

- No more rust problem associated with concrete treads

- Our sizing is better suited to vary the height of the treads

- we have a style for you with our custom options

No more walking on sharp exposed concrete all our pavers are a smooth honed finish with non slip sealer to highlight and protect your pavers.

All our pavers are made with approximately 40 MPA concrete. With such a large variety of colours and stone combinations, we make all our pavers to your specifications.

Call us to discuss your exact requirements as we can provide a solution for just about every project.

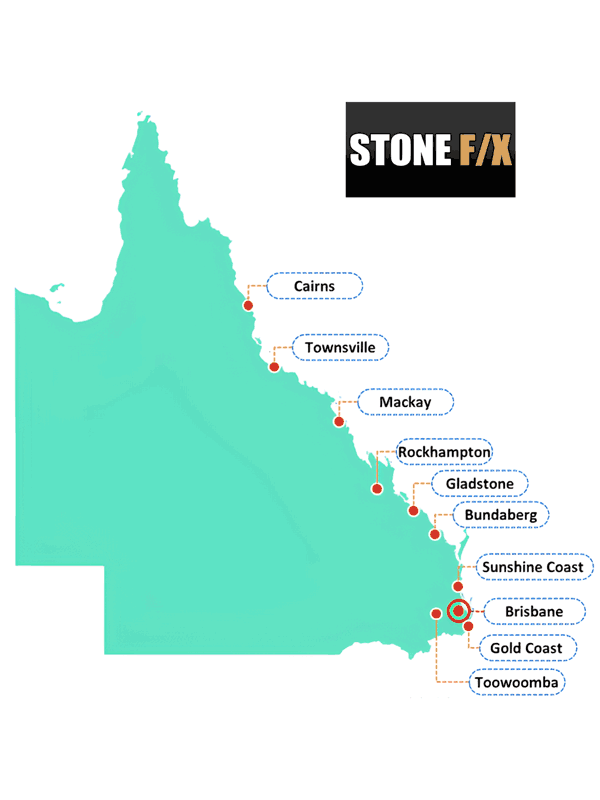

We have an especially strong customer base along the East Coast and all over Queensland. So no matter if you're in Cairns, Townsville, Mackay, Hervey Bay or Gladstone and anywhere in between, we've got you covered.

Maybe you are on the Sunshine Coast, Aurora or Caloundra, we can arrange delivery of our products at competitive rates. Even if you are out west like Toowoomba and Ipswich or across through Logan, Redlands Bay and down to the GOld Coast, we've still got you covered.

Just give us a call or send us an email and we will be able to help you out. We can manufacture and supply our quality products. Don't let your location limit your choice. Contact us to see how.

We Can Help You!

We service the greater region along the east coast of Australia from the Sunshine coast in Queensland down to Sydney and rapidly expanding.

We also have a network of distributors, we can guide you to your nearest retailer.